AERprogress: IIoT Solutions for Oil Free Air Blowers and Compressors

AERprogress: Optimize Your Process Technology with Oil Free Air Blowers and Compressors

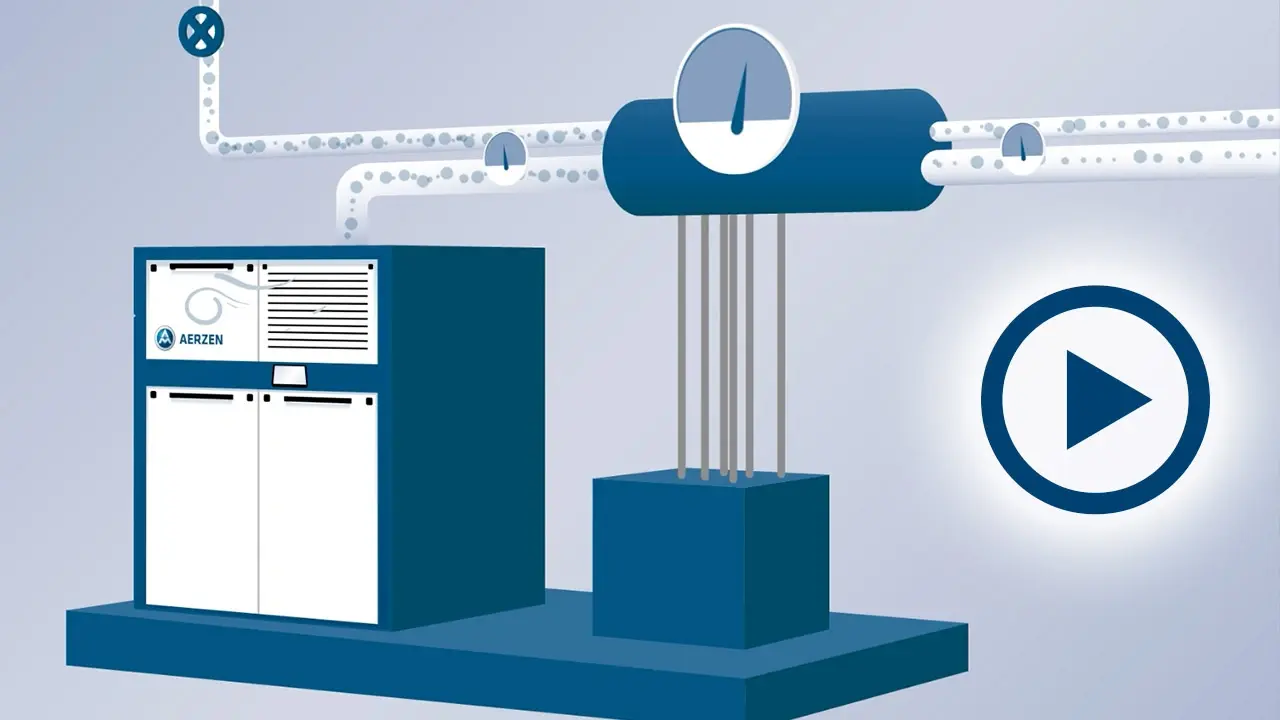

Leverage the power of AERprogress, a cutting-edge IIoT platform designed for the process technology and wastewater treatment plant sector.

What is AERprogress?

AERprogress is a flexible and functional Industrial Internet of Things (IIoT) platform tailored for process technology and wastewater treatment sectors. It supports businesses in optimizing their constantly evolving processes, ensuring efficiency and adaptability to changing circumstances.

This platform is continually being developed to meet new requirements, making it an ideal solution for today's challenges and future developments.

Features of AERprogress

AERprogress offers a range of features designed to make your system and machines transparent, allowing potential errors and optimization opportunities to be identified more efficiently.

- Full Transparency: Real-time monitoring of all systems provides comprehensive insight into machine conditions over time, facilitating optimal adjustments for availability and utilization.

- Digital Twin Technology: A digital replica of all machines installed worldwide, offering both real-time and historical data.

- Vibration Monitoring: Active monitoring of bearing vibrations helps prevent unexpected downtimes and integrates maintenance into operational workflows.

- Digital Maintenance Management: Centralized access to maintenance information improves process efficiency and reduces the need for manual inspections.

- Energy Consumption Transparency: Detailed insights into energy usage enable companies to enhance efficiency, reduce costs, and meet regulatory requirements.

- Error Analysis: Transparent documentation and real-time alerts streamline error analysis and optimize maintenance strategies.

Applications of AERprogress in Process Technology

AERprogress is designed to be used with various types of machinery, including oil-free air blowers and compressors. Its application in sectors such as chemical and cement plants provides numerous benefits, including:

- Improved reliability through proactive maintenance and digital monitoring.

- Enhanced energy efficiency by optimizing machine load profiles and reducing unnecessary consumption.

- Better maintenance management with real-time data and historical records, ensuring minimal disruptions to operations.

Technical Specifications

| Feature | Description |

|---|---|

| Real-Time Monitoring | Access to live data from all systems and components. |

| Data Analytics | Tools for analyzing both real-time and historical data. |

| Maintenance Alerts | Automated notifications for scheduled and unscheduled maintenance tasks. |

| Energy Management | Monitor energy usage to optimize efficiency and reduce costs. |

| Vibration Analysis | Active threshold monitoring for vibration levels to prevent machine failures. |

Why Choose AERprogress for Your Oil-Free Air Solutions?

Choosing AERprogress means opting for a solution that is ready-to-use, scalable, and low-effort. It offers unparalleled access to digital handling for components, adding significant value with new features and benefits.

With the increasing importance of ISO 8573-1 class 0 standards for oil-free air blowers and compressors, AERprogress ensures that your operations adhere to the highest quality standards.

FAQs About AERprogress and Oil-Free Air Solutions

What is an Oil Free Air Blower?

An oil-free air blower is a type of blower that operates without oil lubrication in its compression chamber, ensuring clean air output free of contaminants. It is essential in industries where air purity is critical, such as food and pharmaceuticals.

What is an Oil Free Air Compressor?

An oil-free air compressor generates compressed air without the use of oil in the compression chamber. It is ideal for applications requiring clean air with no risk of contamination, adhering to ISO 8573-1 class 0 standards.

Why Rent a Compressor or Blower?

Renting a compressor or blower provides flexibility and cost-efficiency for short-term or specialized projects. It also eliminates maintenance concerns, as rental services typically include support and servicing.

What Does ISO 8573-1 Class 0 Mean?

ISO 8573-1 Class 0 is the highest air quality standard, indicating zero contamination from oil in the compressed air. This standard is crucial for industries where even the slightest contamination can compromise product quality.

How Does AERprogress Help with Energy Efficiency?

AERprogress helps identify areas of increased energy consumption and provides actionable insights to optimize energy use, reduce costs, and improve overall system efficiency.

Can AERprogress Integrate with Existing Systems?

Yes, AERprogress is designed to be highly flexible and can easily integrate with existing systems, providing a seamless solution for managing and monitoring industrial processes.